حواف JPI7S-15-99 فئة 300

Flange هو نوع من قطع التوصيل التي يمكنها توصيل الأنابيب والصمامات والمعدات. تشمل مزايا الفلنجات ما يلي: 1. مرونة جيدة: وصلة الفلنجات سهلة الفك والتعديل ، وهي ملائمة لصيانة المعدات واستبدالها. 2. الختم الجيد: يمكن لوصلات الفلنجة أن تستخدم حشيات أو حشيات مختلفة لتلبية متطلبات السوائل والضغط المختلفة ، ولها إحكام جيد. 3. قدرة تحمل الضغط القوية: يمكن لوصلات الفلنجات أن تتحمل الضغوط الداخلية والخارجية الكبيرة ، مما يجعلها مناسبة لبيئات العمل القاسية مثل درجات الحرارة العالية والضغط العالي والتآكل. 4. موثوقية عالية: نظرًا لأن وصلة الفلنجة متصلة بواسطة البراغي والصواميل ، فيمكنها ضمان ثبات الاتصال ، وبالتالي تعزيز استقرار وموثوقية المعدات وخطوط الأنابيب. 5. قابلية قوية للتكيف: يمكن اختيار وصلات الفلنجات من مجموعة متنوعة من المواد والأحجام والمواصفات وفقًا للاحتياجات ، ويمكن أن تتكيف مع بيئات ومتطلبات العمل المختلفة.

The JPI7S-15-99 Class 300 flanges manufacturing method has countless blessings and characteristics:

High Quality: The manufacturing technique of JPI7S-15-99The manufacturing technique of JPI7S-15-99 Class 300 flanges provides a number of benefits and characteristics:

High-quality materials: The flanges are produced the usage of magnificent materials such as carbon metal or stainless steel, making sure sturdiness and resistance to corrosion.

Accurate dimensions: The manufacturing technique ensures that the flanges are manufactured with particular dimensions, permitting for suitable suit and compatibility with otherThe JPI7S-15-99 Class 300 flanges manufacturing system presents countless blessings and showcases sure characteristics. Here are some of them:

High-quality production: The manufacturing technique ensures that JPI7S-15-99 Class 300 flanges are manufactured with excessive precision and foremost quality. This lets in for dependable overall performance and sturdiness of the flanges.

Compliance with standards: The manufacturing system follows the JPI7S-15-99 fashionable for Class 300 flanges. This ensures that the flanges meet the required specs and can be used in a vast vary of functions besides any compatibility issues.

Thorough checking out and inspection: The manufacturing technique consists of rigorous checking out and inspection processes to make sure that the flanges meet the essential requirements and fantastic requirements. This helps in handing over defect-free merchandise to the customers.

Efficient manufacturing techniques: The manufacturing technique makes use of environment friendly manufacturing techniques, such as superior machining and fabrication methods. This permits for quicker manufacturing and ensures that the flanges are manufactured with utmost accuracy.

Material options: The manufacturing procedure permits for the use of a number materials, such as carbon steel, stainless steel, and alloy steel, based totally on the particular necessities of the customers. This affords flexibility in phrases of fabric selection, enabling the flanges to be appropriate for exclusive working conditions.

Corrosion resistance: The flanges produced thru this technique are designed to be corrosion resistant, making them appropriate for use in environments the place publicity to moisture, chemicals, or different corrosive components is likely.

Wide vary of sizes: The manufacturing manner can accommodate the manufacturing of JPI7S-15-99 Class 300 flanges in a broad range of sizes, from small to giant diameters. This makes the flanges appropriate for numerous industrial applications.

Customization options: The manufacturing technique lets in for customizable elements and specs primarily based on the precise necessities of the customers. This ensures that the flanges can be tailor-made to meet the special desires of one of a kind projects.

Overall, the JPI7S-15-99 Class 300 flanges manufacturing method affords a mixture of quality, precision, and flexibility, making it a dependable desire for a number of industrial applications.

-99 Class 300 flanges manufacturing method has countless blessings and characteristics:

High Quality: The manufacturing technique of JPI7S-15-99The manufacturing technique of JPI7S-15-99 Class 300 flanges provides a number of benefits and characteristics:

High-quality materials: The flanges are produced the usage of magnificent materials such as carbon metal or stainless steel, making sure sturdiness and resistance to corrosion.

Accurate dimensions: The manufacturing technique ensures that the flanges are manufactured with particular dimensions, permitting for suitable suit and compatibility with otherThe JPI7S-15-99 Class 300 flanges manufacturing system presents countless blessings and showcases sure characteristics. Here are some of them:

High-quality production: The manufacturing technique ensures that JPI7S-15-99 Class 300 flanges are manufactured with excessive precision and foremost quality. This lets in for dependable overall performance and sturdiness of the flanges.

Compliance with standards: The manufacturing system follows the JPI7S-15-99 fashionable for Class 300 flanges. This ensures that the flanges meet the required specs and can be used in a vast vary of functions besides any compatibility issues.

Thorough checking out and inspection: The manufacturing technique consists of rigorous checking out and inspection processes to make sure that the flanges meet the essential requirements and fantastic requirements. This helps in handing over defect-free merchandise to the customers.

Efficient manufacturing techniques: The manufacturing technique makes use of environment friendly manufacturing techniques, such as superior machining and fabrication methods. This permits for quicker manufacturing and ensures that the flanges are manufactured with utmost accuracy.

Material options: The manufacturing procedure permits for the use of a number materials, such as carbon steel, stainless steel, and alloy steel, based totally on the particular necessities of the customers. This affords flexibility in phrases of fabric selection, enabling the flanges to be appropriate for exclusive working conditions.

Corrosion resistance: The flanges produced thru this technique are designed to be corrosion resistant, making them appropriate for use in environments the place publicity to moisture, chemicals, or different corrosive components is likely.

Wide vary of sizes: The manufacturing manner can accommodate the manufacturing of JPI7S-15-99 Class 300 flanges in a broad range of sizes, from small to giant diameters. This makes the flanges appropriate for numerous industrial applications.

Customization options: The manufacturing technique lets in for customizable elements and specs primarily based on the precise necessities of the customers. This ensures that the flanges can be tailor-made to meet the special desires of one of a kind projects.

Overall, the JPI7S-15-99 Class 300 flanges manufacturing method affords a mixture of quality, precision, and flexibility, making it a dependable desire for a number of industrial applications.

الاسميه غليون حجم |

خارج ضياء الشفاه |

ضياء بوري |

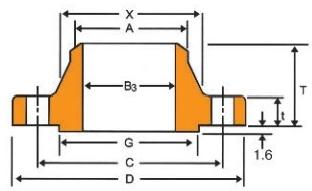

ضياء المحور في شطبة أ |

Dia.of Hub في أساس |

ضياء نشأ وجه |

سميك ل الشفاه |

نصف القطر ل فيليه |

|||||||||||

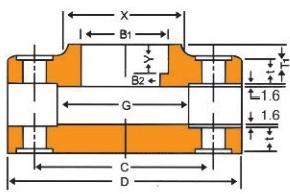

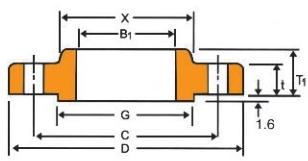

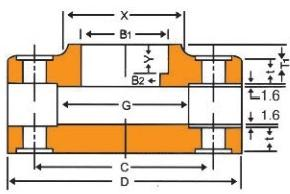

الانزلاق على مقبس B1 |

مفصل لاب B2 |

لحام الرقبة ، المقبس B₃ |

||||||||||||||||

JPI |

أنسي |

|||||||||||||||||

A |

ب |

د |

JPI |

أنسي |

JPI |

أنسي |

SCH40 |

SCH80 |

SCH160 |

SCH40 |

SCH80 |

SCH160 |

JPI |

أنسي |

X |

G |

ر |

R |

15 20 25 |

ح ٪ 1 |

95 117 124 |

22.2 27.7 34.5 |

22.4 27.7 34.6 |

23.4 28.9 35.6 |

22.9 28.2 35.1 |

16.1 21.4 27.2 |

14.3 19.4 25.0 |

12.3 16.2 21.2 |

15.8 20.9 26.6 |

13.9 18.8 24.3 |

11.8 15.6 20.7 |

21.7 27.2 34.0 |

21.3 26.7 33.5 |

38.1 47.8 53.8 |

35.1 42.9 50.8 |

14.2 15.7 17.5 |

3 3 3 |

(32) 40 50 |

(14) 1% 2 |

133 155 165 |

43.2 49.1 61.1 |

43.2 49.6 62.0 |

44.3 50.4 62.7 |

43.7 50.0 62.5 |

35.5 41.2 52.7 |

32.9 38.4 49.5 |

29.9 34.4 43.1 |

35.1 40.9 52.5 |

32.5 38.1 49.3 |

29.5 34.0 42.9 |

42.7 48.6 60.5 |

42.2 48.3 60.5 |

63.5 69.9 84.1 |

63.5 73.2 91.9 |

19.1 20.6 22.4 |

5 6 8 |

65 80 (90) |

2٪ 3 (3٪) |

190 210 229 |

77.1 90.0 102.6 |

74.7 90.7 103.4 |

91.6 78.7 104.1 |

75.5 91.4 104.2 |

65.9 78.1 90.2 |

62.3 73.9 85.4 |

57.3 66.9 76.2 |

62.7 77.9 90.1 |

59.0 73.7 85.5 |

54.0 66.7 |

76.3 89.1 101.6 |

73.2 88.9 101.6 |

100.1 117.5 133.4 |

127.0 104.6 139.7 |

25.4 28.4 30.2 |

8 10 10 |

100 (125) 150 |

4 (5) 6 |

254 279 318 |

141.2 115.4 166.6 |

143.8 116.1 170.7 |

143.0 116.9 168.4 |

116.9 144.6 171.5 |

102.3 126.6 151.0 |

120.8 97.1 143.2 |

108.0 87.3 128.8 |

118.2 102.3 154.2 |

122.3 97.2 146.3 |

109.6 87.3 131.8 |

139.8 114.3 165.2 |

141.2 114.3 168.4 |

146.1 177.8 206.2 |

157.2 185.7 215.9 |

31.8 35.1 36.6 |

11 11 13 |

200 250 300 |

8 10 12 |

381 444 521 |

218.0 269.5 321.0 |

276.4 221.5 327.2 |

271.7 219.5 322.8 |

222.3 277.4 328.2 |

248.8 199.9 297.9 |

237.2 190.9 283.7 |

170.3 210.2 251.9 |

202.7 254.5 303.2 |

242.9 193.7 288.9 |

173.1 215.9 257.2 |

216.3 267.4 318.5 |

219.2 273.1 323.9 |

320.8 260.4 374.7 |

269.7 323.9 381.0 |

41.1 47.8 50.8 |

13 13 13 |

350 400 450 |

14 16 18 |

584 648 710 |

358.1 409.0 460.0 |

359.2 410.5 461.8 |

360.2 411.3 462.4 |

333.4 381.0 428.6 |

317.6 363.6 409.6 |

284.2 325.4 366.8 |

333.3 381.0 428.7 |

317.5 363.6 409.6 |

284.2 325.5 366.7 |

355.6 406.4 457.2 |

355.6 406.4 457.2 |

425.5 482.6 533.4 |

412.8 469.9 533.4 |

57.2 53.8 60.5 |

13 13 13 |

|

500 600 |

20 اربع وعشرون |

775 914 |

511.0 613.0 |

513.1 616.9 |

514.4 616.0 |

477.8 574.6 |

455.6 547.8 |

408.0 490.6 |

477.8 574.8 |

455.6 547.7 |

408.0 490.6 |

508.0 609.6 |

508.0 609.6 |

587.2 701.5 |

584.2 692.2 |

63.5 69.9 |

13 13 |

|

الطول من خلال المحور |

عمق ل قابس كهرباء |

حفر |

ضياء مرفوع وجه ل خاتم مشترك |

ضياء الملعب أو الطوق & أخدود |

جرس

لا. |

نوع RTJ |

الوزن التقريبي (كجم) |

الاسميه غليون حجم |

||||||||||

الانزلاق على المقبس الموضوع |

حجر

ختم |

اللحام رقبة |

يوم بولت سيركل |

رقم ل محل |

ضياء بولت فتحة |

عمق من اخدود |

عرض أخدود |

نصف قطر أخدود |

WN |

S.0 |

س.و |

BL |

||||||

T; |

T2 |

T |

و |

ج |

N |

ك (دقيقة) |

P |

و |

F |

4 |

A |

ب |

||||||

22.2 25,4 27.0 |

22.2 25.4 27.0 |

52.4 57.2 61.9 |

9.5 11.1 12.7 |

66.5 82.6 88.9 |

4 4 4 |

16 19 19 |

51.0 63.5 70.0 |

34.14 42.88 50.80 |

R11 R13 آر 16 |

5.56 6.35 6.35 |

7.14 8.74 8.74 |

0.8 0.8 0.8 |

0.80 1.25 1.58 |

0.65 1.10 1.35 |

0.67 1.12 1.39 |

0.65 1.09 1.38 |

15 20 25 |

C % 1 |

27.0 30.2 33.3 |

27.0 30.2 33.3 |

65.1 68.3 69.8 |

14.3 15.9 17.5 |

98.6 114.3 127.0 |

4 4 8 |

19 22 19 |

79.5 90.5 108 |

60.32 68.28 82.55 |

آر 18 آر 20 ر23 |

6.35 6.35 7.92 |

8.74 8.74 11.91 |

0.8 0.8 0.8 |

2.05 2.93 3.40 |

1.69 2.54 2.92 |

1.74 2.60 3.02 |

1.82 2.70 3.18 |

(32) 40 50 |

(114) (1 هو) 2 |

38.1 42.9 44.5 |

38.1 43.9 44.5 |

76.2 79.4 81.0 |

19.0 20.6 22.2 |

149.4 168.1 184.2 |

8 8 8 |

إثنان وعشرون إثنان وعشرون إثنان وعشرون |

127 146 159 |

123.82 101.60 131.78 |

R26 R31 R34 |

7.92 7.92 7.92 |

11.91 11.91 11.91 |

0.8 0.8 0.8 |

5.10 7.01 8.71 |

4.24 5.94 7.90 |

4.43 6.21 |

4.86 6.90 8.79 |

65 80 (90) |

2٪ 3 (3٪) |

47.6 50.8 52.4 |

47.6 50.8 52.4 |

85.7 98.4 98.4 |

23.8 23.8 27.0 |

200.2 235.0 269.7 |

8 8 12 |

إثنان وعشرون إثنان وعشرون إثنان وعشرون |

175 210 241 |

149.22 180.98.0000 211.12 |

R37 R41 R45 |

7.92 7.92 7.92 |

11.91 11.91 11.91 |

0.8 0.8 0.8 |

11.3 15.1 19.6 |

9.71 12.4 16.2 |

11.6 15.5 21.2 |

100 (125) 150 |

4 (5) 6 |

|

61.9 66.7 73.0 |

95.3 61.9 101.6 |

111.1 117.5 130.2 |

31.8 33.3 39.7 |

330.2 387.3 450.9 |

12 16 16 |

26 29 32 |

302 356 413 |

269.88 323.85 381.00 |

R49 R53 R57 |

7.92 7.92 7.92 |

11.91 11.91 11.91 |

0.8 0.8 0.8 |

30.3 44.3 64.1 |

24.8 35.9 51 |

34.5 53.9 78.9 |

200 250 300 |

8 10 12 |

|

76.2 82.6 89.9 |

111.3 120.7 ※ 130.0 |

142.9 146.0 158.8 |

41.3 44.5 49.2 |

514.4 571.5 628.7 |

20 20 اربع وعشرون |

32 35 35 |

457 508 575 |

419.10 469.90 533.40 |

R61 R65 R69 |

7.92 7.92 7.92 |

11.91 11.91 11.91 |

0.8 0.8 0.8 |

88.3 113 138 |

70.1 90.4 109 |

106 139 175 |

350 400 450 |

14 16 18 |

|

95.2 106.4 |

149.7 152.4 |

161.9 168.3 |

54.0 63.5 |

685.8 812.8 |

.اربع وعشرون اربع وعشرون |

35 42 |

635 749 |

584.20 692.15 |

R73 R77 |

9.52 11.13 |

13.49 16.66 |

1.5 1.5 |

169 248 |

136 204 |

222 340 |

500 600 |

20 اربع وعشرون |

|

مصنعنا

تقطيع المواد الخام

الفحص المعملي

تزوير وتزوير وكبس

تجهيز الالات

شرف تأهيل المؤسسات